AI-Powered IoT Application

REVA Academy for Corporate Excellence – RACE, recently hosted a workshop on “Building an AI-powered application” led by Dr J. B Simha, Chief Mentor, Artificial Intelligence, RACE, REVA University.

The Internet of Things (IoT) is not new; it has been around for over 60 years but has gained popularity because of the internet and connected devices and systems. With the IoT revolution spurred by Industry 4.0 applications, the data collected from various sources every second has exploded. However, the data collected and stored through these IoT devices must be processed and analysed. This workshop threw light on a few critical questions which are often neglected; Who will provide the data? How do you manage data? Who will possess data knowledge? Who and how will the data-driven decisions be made?

What is industry 4.0, for example, is one topic that this blog addresses. What do IoT and AI mean? why is it necessary to combine these two? What is its advantage?

IoT and Industry 4.0

The major value drivers of Industry 4.0 are the resource/process, asset utilisation, labour, Inventories, quality, supply-demand management, time to market, and aftersales services.

- Resource/process includes smart energy consumption, intelligent IoT, and real-time yield optimisation.

- Asset utilization consists of routing flexibility, machine flexibility, remote monitoring and control, predictive maintenance, and augmented reality.

- Labour consists of human-robot collaboration, remote monitoring and control, digital performance management, and automation of knowledge work.

- Inventories include batch size, real-time supply chain optimisation and 3-D printing.

- Quality covers quality management process, advanced process control, and statistical process control.

- Supply-demand match includes data-driven design value and data-driven demand prediction.

- Time to market requires rapid experimentation and simulation, concurrent engineering, and customer co-creation/open innovation.

- service or aftersales: Includes predictive maintenance, remote maintenance, and virtually guided self-services.

One needs to manage the industry 4.0 systems by understanding all of these value drivers. This process of digitizing industry processes has often been called as the “digital twin.” Digital twin projects must answer questions like how to increase the yield through real-time optimization. Can we increase the quality of the product? Can we make the output from manufacturing processes even better?

IoT and AI

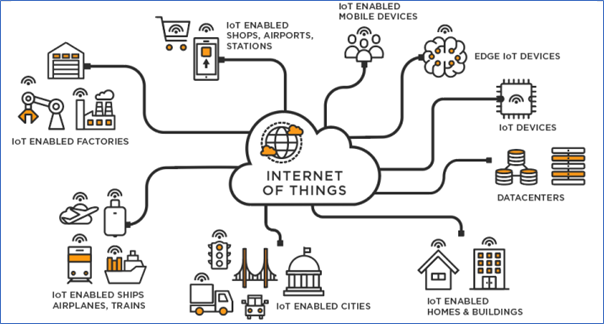

IoT essentially connects everything. It could be an edge device used in a connected system like a linked car.

Internet of Things applications are far wide, including data centres and smart cities; they are all connected with sensors. Sensors measure a few physical and chemical properties and some derived properties. Once measurements are recorded, these must be stored at some place which is called a historian. Most of the time, the data is taken from the ‘historian’. After collecting, IoT analytics is applied.

The model is built and presented to the end users in IoT Analytics. IoT gets the data from multiple systems or from distributed control systems. For instance, if one wants to switch off the fridge from his/her mobile phone, it is called an IoT-enabled refrigerator. If one wants to water the plants in their home when they are away from home, it can be done through, which is called IoT-enabled water sprinkling. This whole system can control, sense, and even monitor.

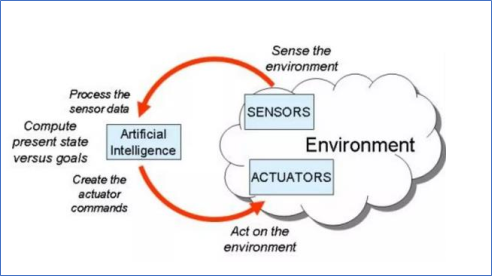

Sense, monitoring, and control are the three things that are expected from an IoT device or an IoT system. If the preset values are there, one can control the system. It does the job, but the question is, who will give that control, ‘knowledge’? where does that control knowledge come from? Where that prediction comes from? These come from what we call artificial intelligence. Artificial intelligence can be as simple as building a linear model or as complex as building a deep learning model.

Artificial intelligence mimics humans. There are two possibilities, one is to get all the knowledge that the human has for a particular job and codify that knowledge and try to use that knowledge with IoT. The second possibility is that the knowledge is so implicit that one cannot explain how the system works. We cannot take out something which cannot be explained, but we can recreate the scenario and try to approximate it. And that is where machine learning comes into the picture. Machine learning can mimic how humans think, which is often called the Turing test. The Turing test is when the result comes out of a machine, and the humans cannot be differentiated; the machine has passed the Turing test! And that is called artificial intelligence.

Artificial Intelligence and Machine Learning -AI and ML

AI and ML Modeling are basically about taking the data, building the model, and learning the relationship between input and output. The outcome of AIML is that, given this input, can one predict the output?

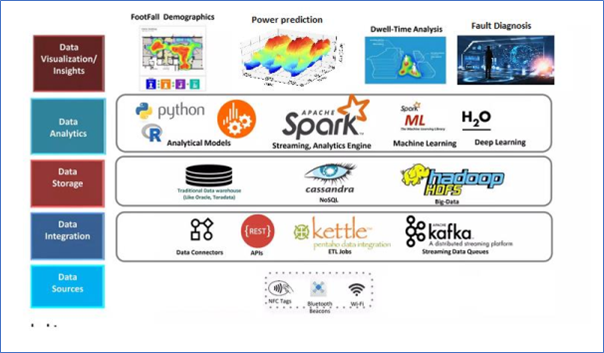

In the technical architecture of AI modelling, the data is collected from the sensors, and data integration and storage can be done through Kafka or Hadoop systems. These stored data may be used to analyze and detect the patterns which will predict the future. At the last level, data is analyzed, where we can build the models using Python, R, Spark etc. There are plenty of IoT data-based use cases.

The integration of IoT data with AIML is very important and crucial for developing an AI-powered IoT application to improve the quality or even to monitor the IoT data set on a large scale. For this, one should have a thorough knowledge of IoT and AI-ML techniques, insight and understanding of the data, and the problem statement. They ought to be able to combine IoT data with an AIML model to provide better outcomes.

Watch the snippets of the workshop to build an end-to-end use case on a prototype involving IoT Historian, AI and ML with Python and deploying with Dash. If you want to learn how to build more such AI applications, join our MTech AI program.